What We Offer

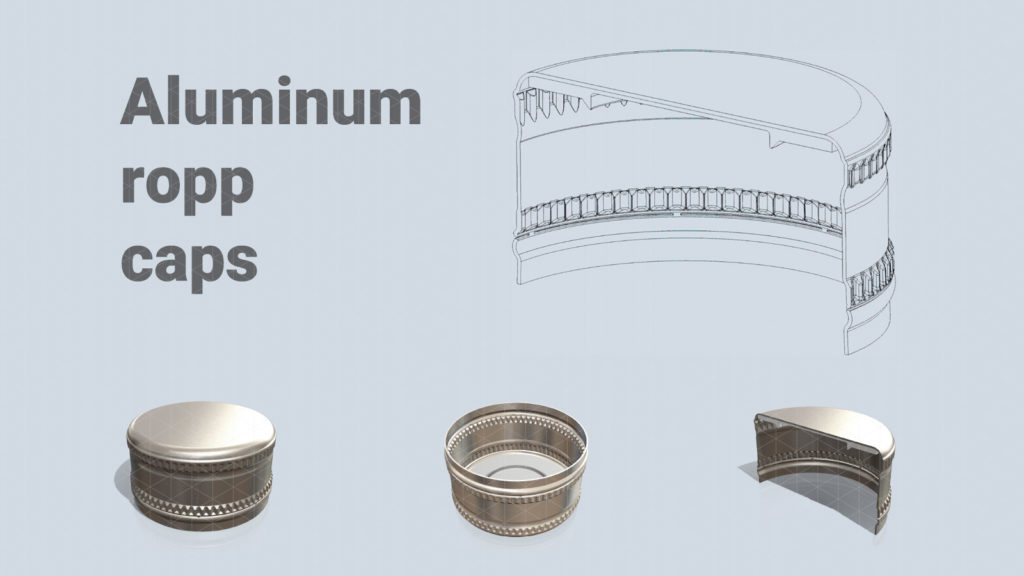

GTl’s closures and containers research facility has developed over decades of doing business and can develop solutions in close collaboration with customers. GTI machines are engineered to produce ropp (roll-on pilfer proof) caps that are cost-effective, provide an effective seal (and barrier), are compatible with contents, easily opened by the consumer, are often reclosable and comply with product, packaging and environmental laws and regulations.

Coating

- Tinplate with a tin coating

- Tin-Free Steel (TFS) with a coating made of Chromium compounds for EOE.

Tin coating

Tin coating is usually a electro tinning process: The tin coating is often flow melted. It gives the Steel for Packaging its attractive brightness. Moreover it makes an alloying layer FeSn2 at the interface between iron substrate and tin, which improves the Corrosion resistance of the tinplate.

* Maximum tin coating defined for welded application only. Other tin coating available on request.

* Marking of differential coatinginaccordance with Euro norm

| Tin Coating (g/m2) | Min (g/m2) | Max (g/m2)* | ASTM |

|---|---|---|---|

| 1 | 0.75 | 1.8 | |

| 1.4 | 1.1 | 2.3 | |

| 2 | 1.6 | 3 | |

| 2.8 | 2.3 | 3.9 | 25 |

| 4 | 3.35 | 5.3 | |

| 5 | 4.2 | 6.5 | |

| 5.6 | 4.7 | 7.2 | |

| 8.4 | 7.15 | ||

| 11.2 | 9.55 | ||

| 14 | 11.95 | Not defined | |

| 15.1 | 12.9 |

Customer Applications

Components type:

- Can End

- Can Lid

- Can Ring

- Welded can body

- Metal Sliplids, etc.

Can/End form, size and volume:

- D50 mm size 200

- D99 mm size 401

- D105 mm size 404

- D139 mm size 509, etc

Packing

Sheet packing for road or rail transportation

- Paper or plastic wrap

- maximum weight (gross or net)

- maximum height if appropriate

- runner length (direction) of the wooden pallets (parallel to short side unless otherwise requested)

- runner height (100 mm unless otherwise requested)

- Paper or plastic wrap

- Hardboard top protection

- Steel edge protections

- 4 straps

Standard Ends

- Prime quality ends are highly standardized products able to satisfy round Shapes demanding retort conditions.

- Proper Seaming of these components onto the can bodies guarantees leak-proof packaging.

- Pressure resistance & seaming ability determines the correct specification.

GTI offers a wide product range of cans as follows

- 200 with TFL EOE

- 401 with RTL.

- 404 with Aluminum EOE.

- 509 with RTL

* Very high strength especially for round standard ends retorted without counter-pressure.

Three-piece (3P)

Three-piece (3P) bodies made by electrical welding have experienced outstanding light weighting in the past. Critical end- use properties are axial resistance for safe palletizing, paneling resistance to withstand retorting pressure constraints, and denting resistance. The capacity to ensure efficient production is related to high-speed welding and flanging performance. The new proposal for metal cost-saving dedicated to small diameter cans or to any cans being processed in mild conditions.

To meet the requirements of various can sizes & can making processes GTIPL offers a wide range of products as follows :

- 200 i.e. 50 mm Dia with TFL EOE.

- 401 i.e. 99 mm Dia with RTL.

- 404 i.e. 405 mm Dia with Aluminum EOE.

- 509 – 139 mm Dia with RTL.

Tins For Food Cans

The food can is an attractive alternative to welded 3P cans for sterilized food. Several processes co-exist, but the most current one nowadays is still:

- Drawing (body maker) and trimming

- Outer protection (base coat +printing +varnishing)

- Flanging + + seaming +beading

- Inside & outside lacquering

- Current can size is 401 (i.e. D 99 mm & H136 mm)

The requirements for food cans are a high-speed process, low earing, and split flange, good surface properties (appearance and lacquer ability) and good mechanical properties of the cans (axial and radial load).

GTI possesses exceptional manufacturing skills and competence in producing aluminum ROPP (roll-on pilfer proof) closures and seals that meet IS standards. These aluminum caps are designed to securely close glass bottles, especially for pharmaceuticals. Engineered for cost-effectiveness, GTI’s ROPP caps provide a strong seal and effective barrier, ensuring the contents remain secure and unaltered. They are compatible with a wide range of contents, easily opened by consumers, and often reclosable, making them highly versatile. Additionally, GTI’s closures comply with stringent product, packaging, and environmental laws and regulations, ensuring safety and quality across various industries.

Key features of GTI production lines:

- Liners made directly inside the aluminum cap shell

- Minimization of production costs

IS Standards for ROPP Caps & Closures, Triple Seal Assembly are as follows:

| PILFER PROOF CAPS & CLOSURES | 22 MM | 25 MM | ALU. INNER SEALS | ALU. OUTER SEALS | ALU. TIKLI |

|---|---|---|---|---|---|

| OUTER DIA | 22.6 +- 0.2 MM | 25.6 +- 0.2 MM | 32.8 – 33. 0 MM | 32.8 – 33. 0 MM | 31.8 – 32.2 MM |

| INNER DIA | 22.2 +- 0.1 MM | 25.2 +- 0.2 MM | 32.4 – 32.6 MM | 33.0 – 33.2 MM | 0 |

| HEIGHT | 15.5 +- 0.2 MM | 16.7 +- 0.2 MM | 10.3 -10.5 MM | 11.2 – 11.4 MM | 0 |

| WEIGHT | 1.6 +- 0.1 GM | 1.1 +- 0.2 GM | 2.3 – 2.5 GM | 2.3 – 2.5 GM | 2.3 – 2.5 GM |

| THICKNESS OF WAD | 1.3 – 1.7 MM | 1.7 – 1.9 MM | ————– | ————– | ————– |

| PERFORATION HEIGHT | 11.3 – 11.5 MM | 12.4 – 12.6 MM | ————– | ————– | ————– |

| OUTER DIA OF EPWAD | 21.5 +- 0.15 MM | 24.5 +- 0.15 MM | ————– | ————– | ————– |

Available Standards

| AMFCE | EN10202 | Old EN | ASTM | Annealing | Reduction | Yield Stress (MPa) | Thickness range | Main End Use |

|---|---|---|---|---|---|---|---|---|

| TS230 | TS230 | TSO | T1 | BA | SR | 230 | 0.16 • 0.49 | Bakeware |

| TS245 | TS245 | T52 | T2 | BA | SR | 245 | 0.16 • 0.49 | General line |

| TS260 | TS260 | T55 | BA | SR | 260 | 0.16 • 0.49 | Expanded cans | |

| TS275 | TS275 | T57 | BA | SR | 275 | 0.16 • 0.49 | General purpose | |

| TS290 | TS290 | T59 | T4 | BA | SR | 290 | 0.16 • 0.49 | Aerosol tops |

| TS340 | BA | SR | 340 | 0.16 • 0.49 | Can bodies & ends | |||

| TS480 | BA | DR | 480 | 0.14 – 0.49 | 3P can bodies | |||

| TS500 | BA | DR | 500 | 0.14 • 0.34 | 3P can bodies | |||

| TS520 | DR520 | DR7.5 | BA | DR | 520 | 0.14 – 0.30 | 3P can bodies | |

| TS550 | DR550 | DRS | BA | DR | 550 | 0.12 – 0.30 | 3P can bodies | |

| TH330 | CA | SR | 330 | 0.16 • 0.49 | Drawn can bodies | |||

| TH360 | CA | SR | 360 | 0.16 • 0.49 | Drawn can bodies | |||

| TH415 | TH415 | T61 | T4 | CA | SR | 415 | 0.16 – 0.49 | 3P can bodies, crown corks |

| TH435 | TH435 | T65 | TS | CA | SR | 435 | 0.16 – 0.49 | 3P can bodies, can ends |

| TH460 | CA | DR | 460 | 0.14 • 0.49 | Can ends, easy-open ends | |||

| TH480 | CA | DR | 480 | 0.13 • 0.40 | 3P can bodies | |||

| TH520 | TH520 | DR520 | DR7.5 | CA | DR | 520 | 0.13 – 0.40 | 3P can bodies, tabstocks |

| TH550 | TH550 | DR550 | DRS | CA | DR | 550 | 0.13 • 0.38 | 3P can bodies, tabstocks, aerosol tops and bottoms |

| TH580 | TH580 | DR580 | DRS.5 | CA | DR | 580 | 0.13 – 0.38 | Twist-off caps, drawn cans |

| TH620 | TH620 | DR620 | DR9 | CA | DR | 620 | 0.13 • 0.34 | Twist-off caps, can ends |

E 2.8/2.8 means tin weight of 2.8 g/m2 on each side of the sheet. Temper and annealing type: T 57 – T3 BA (ASTM).

Technical information:

Metallic coating: Tinplate (TP)

Tin coating: specify coating masses on each side (E for equally coated, D for differential coated, D shall be adjacent to the surface to be marked).

Dimension in mm:

- For coils: thickness x width

- For sheets: thickness x rolling width x cut length